The main challenge that cement producers face is the way they lower their carbon footprint economically, as well as improve their contributions towards sustainability by adopting alternative fuels. But, fort his,, they ideally need to be capable of productively and accurately handling mixed fuels. Addressing this issue, Schenck Process have engineered a dynamic feeder especially for the cement industry – the MultiFlex NG Feeder.

Alternative fuel materials used in the production of cement, can come in a wide variety of thicknesses, shapes, coarseness and types. Materials may vary from household waste, dried sewage sludge and derivative fuels, through to organic waste and tyre chips. Having a feeder that is capable of flexibly adapting to process materials with these variabilities, without causing unnecessary maintenance and downtime, is the main challenge.

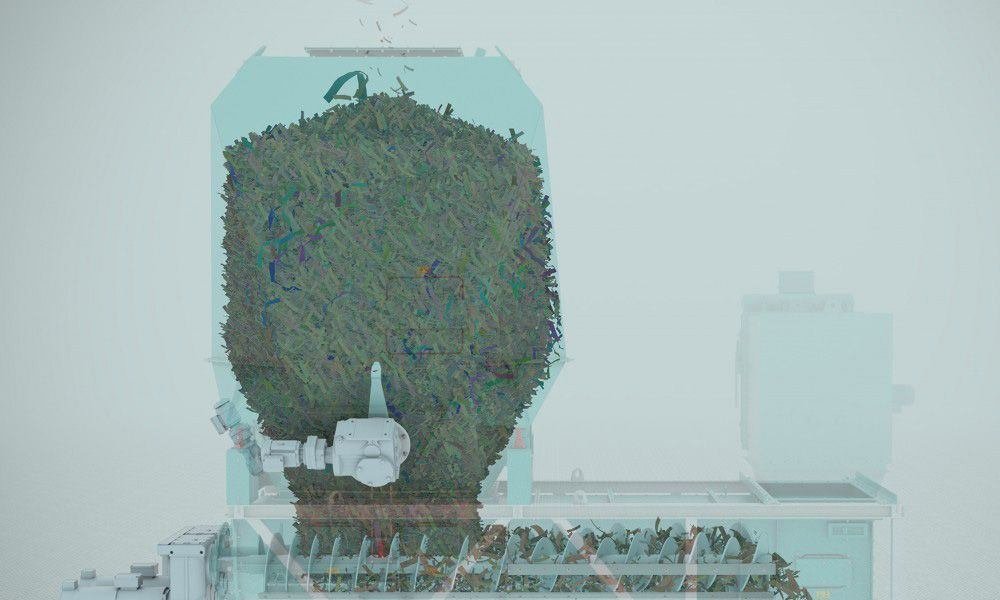

Schenck Process have therefore designed the MultiFlex NG Feeder with a number of features that makes processing mixed fuels – efficient, precise, consistent and cost effective.

Initially to control the filling, an advanced weighing system allows automatic calibration. Continuous calibration of the combined weighing system has been engineered into the MultiFlex Feeder, to yield long term accuracy of +/- 1%. This leads to less system wear from varying materials, longer life performance and lower energy consumption.

For ensuring accurate and proper filling of the screws, the material inlet of the screw trough is weighed. This also also enables control of speed. Material bridges in the hopper are detected and activating agitators maintain correct feeding of the trough. This occurs only when necessary, for high energy efficiency and system lifespan as the main challenge.

The screw trough is weighed prior to material discharge, thereby controlling the mass flow of material, relative to the speed of the conveying screws. Synchronising sensors continuously adjust the phase of each conveying screw, to prevent material bundling when feeding variable materials and to maintain a smooth flow. For small feedrates, single or double screws, allow for a wide control range.

Other features of the MultiFlex NG include ATEX and reduced explosion design, as well as robust construction for maximum wear protection.

Ultimately, cement producers are under more pressure than ever to ecologically improve their production processes. Using a variety of alternative fuels to do so, demands both efficiency and stability. The flexible design of the MultiFlex NG Feeder from Schenck Process, not only allows for high accuracy and consistent feeding of many materials, but also increases the operational lifespan of the system.

Supporting the ethos of enabling a greener future, the MultiFlex NG since its launch of March 2021, has turned approximately 2.6 million tonnes of plastic into energy. While, every hour it helps save the environment from 500 tonnes of plastic. All these are ecological benefits that cement producers can also reap from and pass on.

Souce: Schenck Process