Customer: Selma Oak Flooring

SIC Code: 2426

Application: Oak and laminated flooring manufacturing facility

The situation:

“We use conveyors throughout the whole manufacturing, rework, and recycling process,” says Dave Clark, the plant’s manufacturing operations manager. “We used to do a lot of hand carrying or moving around the material on skids and in carts. Three or four people were needed to transport the rework or recovery items alone.

Besides its ergonomic impact, the old handling operation suffered from another problem that detracted from needed productivity. It was too slow to meet market demands.

The desired solution:

Selma needed to reduce the physical handling of both work-in-process and waste while at the same time increasing the output of finished product to meet rising market demands in a timely manner.

Solution implemented:

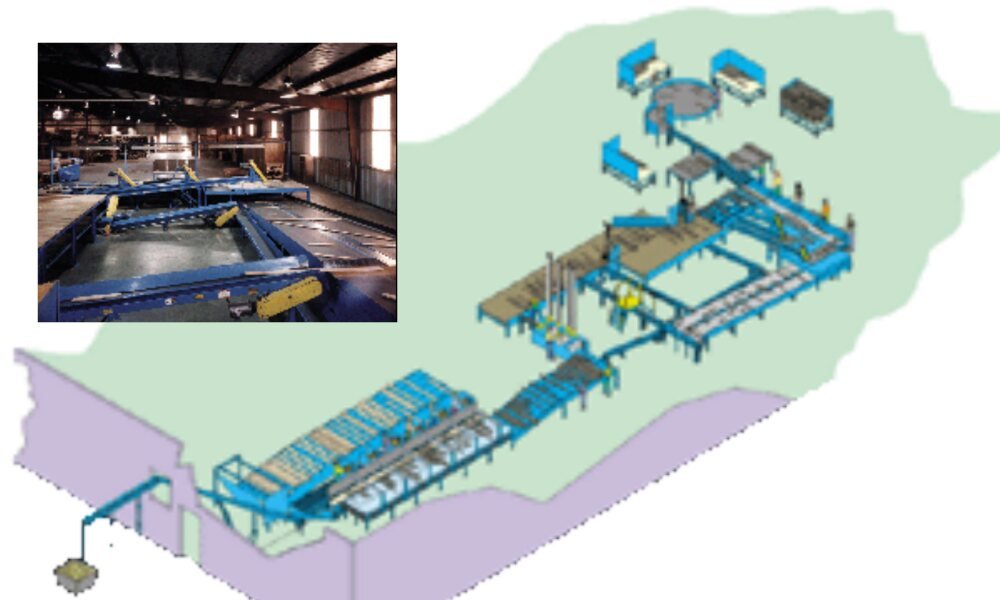

Key to this upgrade was the introduction of Hytrol conveyors – primarily horizontal belt conveyors—at critical parts of the flow process. The Selma Oak Flooring operation is simple and cost-effective. It gets the job done smoothly and efficiently without the need for costly computer controls. The designers also made the system compact so that it could fit in the existing building configuration.

With the new system, the “green” raw material is introduced into the conveyorized materials-flow process after it’s fully air-dried or dried by kiln. Saw operators remove knots and other imperfections from board that has been placed on slat conveyors in front of them. The length of the cut wood can range anywhere from 82 inches down to 12 inches. The cut pieces then move on another slat conveyor where the tongue-and-groove operators square them away in preparation for movement through dust-removing ventilators. After ventilation, the wood moves onto another set of slat conveyors that leads to the quality control station. There an operator separates the waste and scrap from the good-quality pieces.

The scrap material moves on a Hytrol TA horizontal belt conveyor that links up with another TA conveyor running the length of the building. This is the main scrap-removal conveyor line. It includes an incline section that takes the waste material up and outside of the plant to an outdoor recycle bin. This automated scrap flow system replaces the old method of removing trash, which was largely a manual operation. In addition, it eliminates the problem of scrap falling onto the floor or having to be placed in dump carts, thereby creating congestion.

The good wood moves on to the sorting stations. At this point, operators place the pieces on a Hytrol chain-drive conveyor, which feeds into one of three TR belt conveyors. These belts, which have angled sides that minimize damage to the wood and prevent scraps from falling into the bearing mechanisms, feed into the final quality control station. At this critical juncture in the process, operators carefully examine the pieces for any blemishes. First-quality wood travels on a takeaway conveyor to the shipment preparation stations.

The results:

Since Selma Oak Flooring completed installation, production has increased by more than 40 percent and labor savings have exceeded 25 percent.

The new conveyor system reduces wear and tear on the company’s employees by lessening the number of times material has to be manually handled.

Simplicity, efficiency, and compactness are the hallmarks of this installation. Reflecting on his experience with the new system, Dave Clark concludes, “The conveyors have improved every aspect of our operation – people, productivity, and costs.” This means that Selma Oak Flooring can stay on top of the booming demand for its product.

Facility Information

Application: Floor manufacturing

Facility Size: 150,000 square feet

Employees: 106 (per shift)

Product Handled: 3/4-inch oak

Key Material Handling Hardware: TA and TR belt, chain drive conveyors

Source;www.cisco-eagle.com